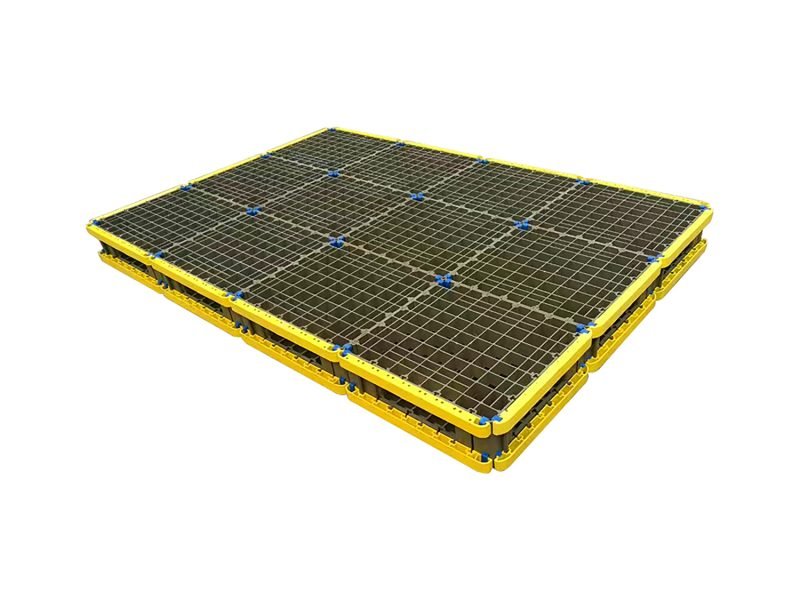

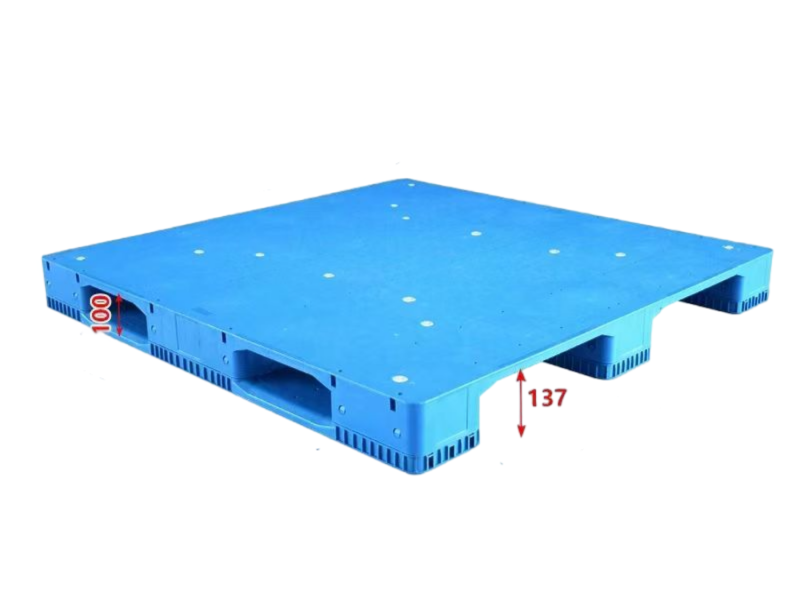

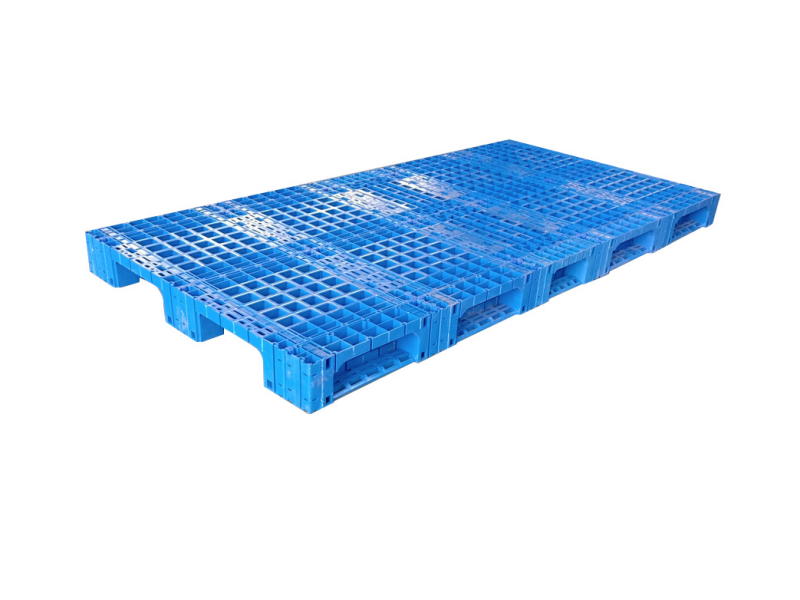

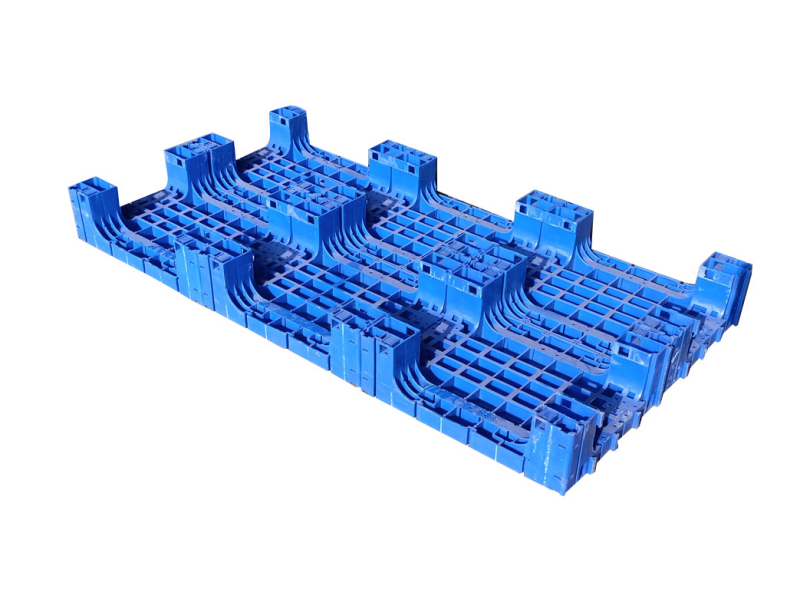

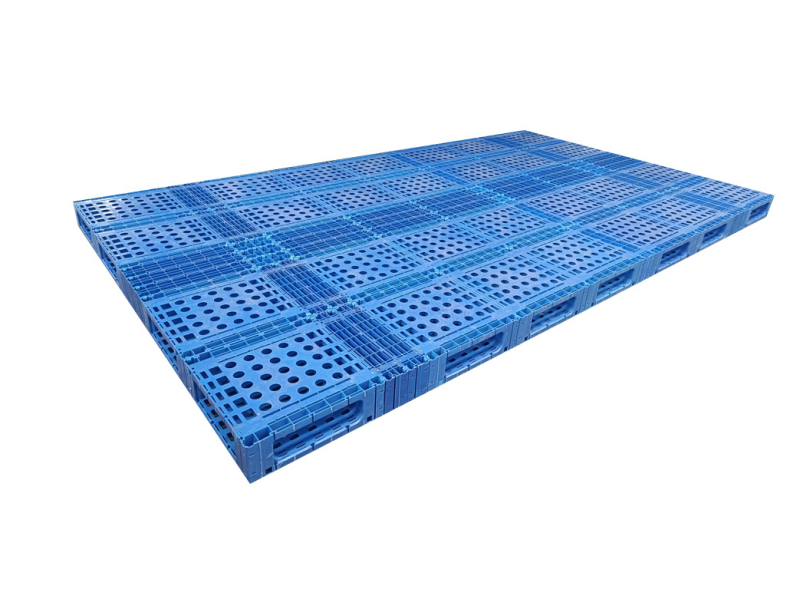

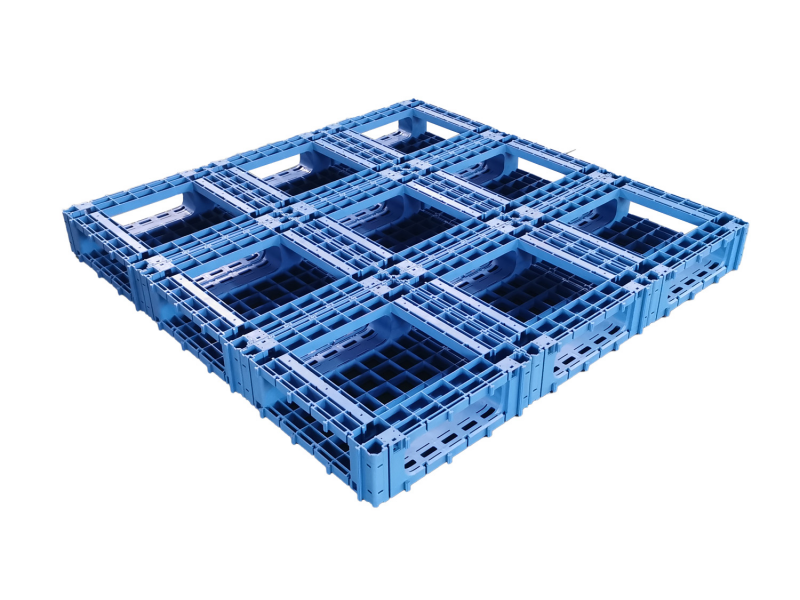

A modular plastic pallet—also called a spliced pallet, interlocking pallet, or joint pallet—is built for oversized or irregular goods that standard pallets can’t handle. Made from injection-molded HDPE or PP, plastic panels can be connected to form custom sizes over 1600mm wide. We offer two structures: 3-runner, 9 legs or double-face, both with a mesh deck and reinforced base.

Most models stack securely up to 3–5 layers on flat ground. All pallets can be reinforced with steel tubes for heavy-duty loads. They’re suitable for floor use, ground stacking, and rack placement when size and structure allow. If your load doesn’t fit, this is the pallet you build to match it.