Plastic pallet box

Elevate your logistics with our diverse and robust Plastic Pallet Boxes, tailored for various industry requirements. Our range includes:

Enlightening Pallet's Product Range: Specializing in Plastic Pallet Boxes

At Enlightening Pallet, we are proud to be at the forefront of the plastic pallet box industry, dedicated to innovating and manufacturing high-quality plastic pallet boxes. Our commitment to excellence is evident in our provision of reliable, recyclable, and eco-friendly plastic pallet box solutions, catering to a broad range of global customers.

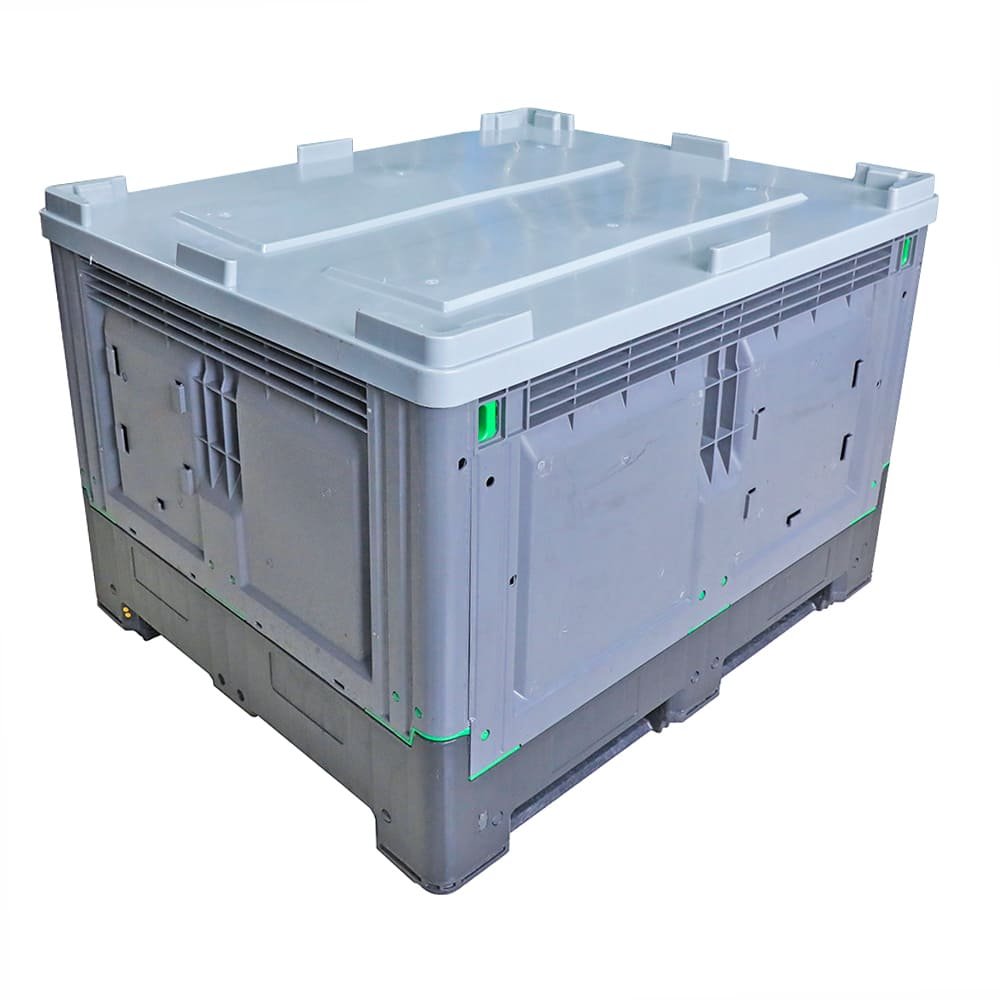

Rigid Plastic Pallet Boxes

Ideal for bulk storage and distribution, offering stackability and easy cleaning.

Vented Plastic Pallet Boxes

Perfect for storing and transporting perishables, ensuring air circulation to keep them fresh.

Collapsible Plastic Pallet Boxes

Space-saving for return transport, easily collapsible yet sturdy.

Enlightening Pallet offers a diverse range of three primary plastic pallet box types: Rigid, Vented, and Collapsible. Each is designed to meet specific storage and transportation requirements, with features catering to various applications:

Rigid Plastic Pallet Boxes: Ideal for robust and continuous use, these boxes excel in bulk storage, distribution, and recycling. They are designed for strength, durability, and are easily stackable.

Vented Plastic Pallet Boxes: These boxes are specifically designed for scenarios requiring ventilation, making them perfect for perishable goods storage and transport. They ensure optimal air circulation to maintain product quality and freshness.

Collapsible Plastic Pallet Boxes: Tailored for space and fuel efficiency, particularly valuable during return transport. These boxes can be folded down when not in use, providing exceptional capacity while retaining their sturdiness.

At Enlightening Pallet, we also specialize in customized solutions. Our expertise allows us to tailor plastic pallet boxes beyond these core models to suit your specific operational needs, whether it’s load capacity, size, or other unique features. Our commitment is to deliver pallet boxes that perfectly integrate into your logistics and storage processes, enhancing efficiency and effectiveness.

Get Your Free Plastic Pallet Catalog Today!

Discover a range of durable and sustainable plastic pallets in our catalog. From heavy-duty to export and food-grade options, find the perfect solution for your logistics needs. Request your free catalog today for efficient, eco-friendly pallet choices.

Why Enlightening Pallet is Your Go-To for Plastic Pallet Boxes

Enlightening Pallet combines innovation and experience to deliver superior plastic pallet box solutions. Recognized globally, we cater to various industries with our eco-friendly, durable, and cost-effective plastic pallet boxes.

Customized Solutions for Diverse Needs

Understanding the unique demands of each client, we specialize in creating tailor-made plastic pallet boxes, ensuring they meet your specific needs for efficiency, safety, and sustainability in areas like fruit storage, bulk transport, and more.Advanced Manufacturing for Versatile Boxes

Utilizing the latest production technologies, our plastic pallet boxes, including fruit plastic pallet boxes and collapsible bulk containers, are designed to address the evolving needs of industries like agriculture, pharmaceuticals, logistics, and beyond.

State-of-the-Art Production Facilities

With two modern production bases housing over 100 specialized machines, we are capable of manufacturing high-quality plastic pallet boxes. Our products lead the market in strength, longevity, and versatility.Competitive Pricing for Premium Quality

We believe in offering top-quality solutions at competitive prices. Our range, including bulk container express options, is priced to provide the best value, catering to businesses of all sizes.

Enlightening Pallet is committed to being your ideal partner for all plastic pallet box needs, offering premium products that enhance the efficiency and sustainability of your operations.

Enlightening Pallet: Trusted by 450,000+ Satisfied Clients Your Invitation to Join

Your Comprehensive Guide to Plastic Pallet Boxes

Plastic Pallet Boxes are essential in modern logistics, providing robust solutions for transporting and storing goods. They stand out for their durability, hygienic design, and versatility in various environments.

What is a Plastic Pallet Box?

A Plastic Pallet Box is a versatile storage and transport tool, akin to how an oscillating knife offers precise cutting. These boxes, available in forms like fruit plastic pallet boxes, collapsible bulk containers, and bulk container express options, provide exceptional stability and protection for goods. They are indispensable in industries that require meticulous handling, such as food, medicine, and logistics. The design of these pallet boxes ensures safe, secure, and efficient movement and storage of materials. They offer the same level of precision and efficiency in handling goods as an oscillating knife does in cutting, making them invaluable in streamlined logistics operations.

Brief History of Plastic Pallet Boxes

The history of plastic pallet boxes is intertwined with the development of plastic pallets, which traces back to the period after World War II. The exact origin of plastic pallet boxes isn’t clearly documented, but they likely evolved alongside plastic pallets as part of the broader shift in materials used for logistics.

While the specific history of plastic pallet boxes isn’t as detailed, it’s likely that they evolved as an extension of these developments. The need for durable, versatile, and hygienic storage solutions in various industries probably propelled the innovation and widespread adoption of plastic pallet boxes. These boxes have since become integral to supply chain management, offering a reliable alternative to traditional wooden boxes and containers.

Advantages of Plastic Pallet Boxes

Plastic Pallet Boxes offer numerous benefits for a range of logistics applications, including specialized types like fruit plastic pallet boxes, transport pallet boxes, and mesh pallet boxes:

- Enhanced Durability: These boxes have a longer lifespan than traditional options, enduring extensive use without significant wear.

- Superior Load Handling: Designed for optimal stability, they distribute weight evenly, providing a secure platform for various goods.

- Lightweight and Energy Efficient: Their lighter weight reduces transportation energy use, potentially cutting freight costs.

- Eco-Friendly: Made from materials like HDPE and PP, these boxes are durable and contribute to a sustainable supply chain.

- Cost-Effective: Despite initial costs, their durability and reusability offer long-term savings.

- Hygienic and Easy to Clean: Resistant to moisture, chemicals, and pests, they maintain high hygiene standards, ideal for food and pharmaceutical industries.

- Aesthetic and Customizable: Available in different designs, they can be customized for branding, enhancing logistics visuals.

- Operational Efficiency: Their design streamlines handling and storage, saving labor and time in logistics operations.

Plastic Pallet Boxes, in various forms like collapsible, rigid, or vented, provide comprehensive benefits, making them a preferred choice in modern supply chain management.

Design Guide for Plastic Pallet Boxes

Our approach to designing Plastic Pallet Boxes, such as foldable pallet boxes, apple fruit plastic pallet boxes, and Foldable Bulk Containers, is centered on meeting the diverse requirements of various industries. Here are some key features and benefits based on current market innovations and customer needs:

Stackability: Designed for secure stacking, optimizing storage and transportation space. Interlocking corners provide additional stability, minimizing the risk of damage or collapse during transport.

Foldability: Some models feature collapsible sides for compact storage, reducing shipping and handling costs, and facilitating container return and reuse. This feature is particularly beneficial for collapsible pallet boxes.

Customizability: Available in various sizes, shapes, and colors, with options for labeling and branding to meet specific requirements and enhance product identification and tracking.

Security: Certain designs include locking mechanisms for added security, preventing unauthorized access or tampering, especially important for high-value or sensitive products.

Durability and Repairability: Resistant to weather, moisture, rotting, cracking, and corrosion. Unlike wood pallets, plastic pallets maintain structural integrity in all conditions and can be repaired instead of replaced, offering long-term cost savings.

Economic Advantages: Efficient design with a high return ratio when folded, allowing more empty containers to be transported at once. Manufactured from recycled plastics and fully recyclable at the end of life.

Enhanced Space Utilization: Collapsible designs maximize space in warehouses and during transport. Lightweight compared to metal bins, leading to efficient cubing out of trucks.

Circular Design: Use of recycled material in production reduces CO2 emissions, aligning with sustainability targets. These boxes can be used repeatedly and recycled at end of life.

By choosing the right Plastic Pallet Box with these innovative features, businesses can optimize their logistics operations, reduce costs and waste, and ensure safe and efficient transport of products.

Selecting the Right Plastic Pallet Box

For effective business operations, choosing the ideal Plastic Pallet Box is crucial. Whether it’s Folding Pallet Boxes or Apple Fruit Plastic Pallet Boxes, these factors will ensure optimal compatibility with your needs:

- Weight Capacity: Assess the box’s load capacity, considering dynamic and static weights. The choice of size, design, and materials is pivotal for secure item handling.

- Dimensions: Match boxes to your cargo size and transportation requirements, with a variety of sizes for different logistics.

- Material Quality: Opt for superior materials like HDPE or PP, offering benefits in strength and resistance. Your choice should be informed by hygiene, load requirements, and environmental conditions.

- Nestability and Stackability: For effective space utilization, choose nestable and stackable pallet boxes to enhance logistics efficiency.

- Hygiene and Cleanliness: Prioritize boxes that are easy to clean and resist moisture, especially for hygiene-critical environments. Plastic boxes are advantageous over wood in preventing splintering and bacterial infestation.

- Cost-Effectiveness: Balance upfront costs with long-term benefits. Plastic pallet boxes are durable and low maintenance, offering cost savings over time.

- Eco-Friendliness: Select boxes made from recycled materials and those that are recyclable, supporting sustainability and reducing environmental impact.

Applying these strategies will enhance your website’s performance on Bing, leading to improved visibility and customer engagement for your plastic pallet boxes.

Understanding Pricing for Plastic Pallet Boxes

When considering the pricing of Plastic Pallet Boxes, including variants like Foldable Bulk Crate, Collapsible Pallet Box, and Foldable Box Pallet, key factors to consider include:

Material Composition: The type of material used, such as high-density polyethylene (HDPE) and polypropylene (PP), significantly impacts pricing. Different polymers offer varying strengths and impact resistance, with premium-grade materials generally costing more due to their improved durability and functionality.

Production Method: The manufacturing method (thermoforming, blow molding, or injection molding) affects costs. Each method has unique benefits and financial implications, with thermoformed pallets sometimes being less expensive than injection-molded pallets, which provide good dimensional uniformity.

Design and Specifications: The design, including size, weight capacity, and reinforcement features, influences manufacturing costs. Customized designs or specifications to meet specific industry standards can increase the price due to added manufacturing complexity.

Order Volume: The number of pallets ordered and the total order size can affect pricing. Bulk orders usually reduce the per-unit cost through economies of scale, while smaller orders might have higher prices.

Market Supply and Demand: Fluctuations in market demand and supply significantly affect pricing. Costs may increase if demand exceeds supply, leading to competition and scarcity, while excess supply might lead to more competitive pricing as producers seek to clear extra stock.

Additional Features and Customizations: Features like anti-slip surfaces, RFID tags, and custom labeling enhance functionality but can raise costs. It’s important to assess the necessity of these features based on specific industrial needs to avoid unnecessary expenses.

Understanding these factors is crucial for selecting the right Plastic Pallet Boxes for your business, ensuring you get the best value and functionality that aligns with your specific requirements.

Manufacturing Process of Plastic Pallet Boxes

The production of Plastic Pallet Boxes, including Foldable Bulk Crates, Collapsible Pallet Boxes, and Foldable Box Pallets, utilizes several advanced manufacturing techniques to ensure durability, functionality, and cost-efficiency:

Injection Molding: Widely used for its ability to create durable and detailed pallet boxes. This process involves melting materials like PP or HDPE and injecting them into molds, ideal for mass production of strong and intricate designs.

Low Pressure Structural Foam Molding: This method blends plastic with an inert gas to produce pallet boxes with a high strength-to-weight ratio. It’s cost-effective and allows for design flexibility while using less material.

Thermoforming: In this method, plastic is heated, formed over a mold, and cooled. It includes vacuum forming or pressure forming, with the latter allowing more detailed designs. Thermoformed pallet boxes are valued for their versatility and widespread use in various supply chain applications.

Leading Pallet Boxes manufacturers choose these processes based on specific product requirements, balancing factors like strength, design complexity, and cost.

Material Selection for Plastic Pallet Boxes

Choosing the right materials for Plastic Pallet Boxes, including Foldable Box Pallet, Collapsible Pallet Box, and Reusable Bulk Containers, is essential for ensuring their durability, functionality, and cost-effectiveness:

Polypropylene (PP): Selected for its strength yet lightweight nature, ideal for maneuverable pallet boxes. PP is resistant to chemicals and moisture, making it suitable for harsh conditions.

High-Density Polyethylene (HDPE): Used for its strength, rigidity, and impact resistance, HDPE is perfect for heavy-duty boxes. Its chemical and moisture resistance enhances versatility.

Polyolefin: Combining PP and HDPE, polyolefin offers both materials’ strengths – durability and lightweight properties. This cost-effective option can be molded into various shapes and is chemical and moisture resistant.

Fiberglass: Chosen for its strength, light weight, and corrosion resistance, fiberglass is ideal for pallet boxes exposed to high temperatures or harsh chemicals, suitable for industries like food or pharmaceuticals.

Recycled Plastics: Emphasizing sustainability, recycled plastics reduce environmental impact while maintaining quality.

These materials, processed through manufacturing techniques like injection molding, ensure Plastic Pallet Boxes are stable, capable of bearing significant loads, and resistant to impact, aligning with various industry requirements.

Why Choose Enlightening Pallet for Your Plastic Pallet Box Needs?

Enlightening Pallet stands out in the market for meticulously crafting Plastic Pallet Boxes tailored to your unique needs. We specialize in using high-grade materials like HDPE, PP, and fiberglass, creating a range of pallet box styles that cater to diverse requirements.

Our team collaborates closely with clients to develop customized solutions, ensuring each pallet box meets your specific demands. Partnering with top manufacturers, we assure superior quality in our products.

By choosing Enlightening Pallet, you opt for more than just a product – you choose excellence, sustainability, and a commitment to customer satisfaction in every Plastic Pallet Box we deliver.

Comparative Benefits of Plastic Pallet Boxes Versus Wooden Boxes

When comparing plastic pallet boxes to wooden boxes, several key advantages of plastic pallet boxes become evident:

Durability and Longevity: Plastic pallet boxes, like Foldable Box Pallets and Collapsible Pallet Boxes, are more durable and long-lasting compared to wooden boxes. They withstand the rigors of repeated use in transit, making them a cost-effective choice for closed-loop systems. Unlike wooden boxes, which typically offer limited usage, plastic pallet boxes can be reused many times, reducing the need for frequent replacements.

- Environmental Friendliness: Plastic pallet boxes are often made from recycled materials and are themselves recyclable, contributing to a reduction in waste. By choosing plastic over wood, there’s a decrease in tree consumption and overall resource use. These boxes do not end up in landfills as often as wooden boxes, lowering disposal and landfill costs.

Weight and Handling: Plastic pallet boxes are generally lighter than wooden boxes, facilitating easier handling and reducing shipping costs. This weight difference can be significant in logistics, especially in air freight and export scenarios.

Storage Space Efficiency: Many plastic pallet box designs, such as nestable models, save a considerable amount of storage space when not in use. In contrast, wooden boxes typically come in a limited number of sizes and do not offer this nestability feature, making them less efficient for shipping and storage

Hygiene and Maintenance: Plastic pallet boxes do not absorb humidity and are resistant to dampness, making them more suitable for clean and hygienic applications. They can be easily cleaned and prepared for reuse, whereas wooden boxes absorb moisture, change weight, and can deteriorate over time. The risk of contamination is higher with wooden boxes due to their tendency to harbor pests and require stringent decontamination processes.

Customization and Branding: Plastic pallet boxes offer diverse customization options, including color choices and high-quality branding. They can be easily marked with barcodes and RFID for tracking, whereas wooden boxes typically have limited customization and branding capabilities.

Suitability for Automated Systems: Due to their uniformity and consistent surface, plastic pallet boxes work well in automated systems, reducing the risk of jamming, which is a common issue with the variable surfaces of wooden boxes.

In summary, plastic pallet boxes provide significant advantages over wooden boxes, including enhanced durability, environmental friendliness, lightweight design, storage efficiency, hygiene, customization options, and suitability for automated systems. However, it’s important to also consider the context of use and specific requirements of the application when making a choice between plastic and wooden options.

Industries Utilizing Plastic Pallet Boxes

Plastic Pallet Boxes, including varieties like Pallet Boxes for Fruits and Vegetables, Collapsible Plastic Pallet Boxes, and HDPE Plastic Pallet Boxes, are widely used across several industries:

Agriculture and Horticulture: Ideal for storing and transporting fruits and vegetables, these pallet boxes offer ventilation, durability, and hygiene.

Retail and Warehousing: Their collapsibility and ease of storage make them a preferred choice for retail storage and display, optimizing space utilization.

Food and Beverage Industry: The hygienic and non-absorbent properties of these boxes ensure safe and clean storage for food items.

Logistics and Shipping: The robust and reusable nature of plastic pallet boxes, along with their ability to withstand various environmental conditions, makes them invaluable in logistics.

Pharmaceuticals and Healthcare: Ensuring contamination control and cleanliness, these boxes meet the stringent requirements of the pharmaceutical industry.

The adoption of plastic pallet boxes in these industries is driven by their versatility, cost-effectiveness, and sustainability, aligning with modern logistical demands and environmental concerns.

Best Practices for Handling and Use of Plastic Pallet Boxes

When handling and using Plastic Pallet Boxes, consider the following best practices to ensure safety and longevity:

Choosing the Right Box: Select a box based on the type and weight of the contents it will carry. Different boxes have varied weight capacities and are suitable for different types of goods.

Inspecting and Preparing the Box: Check the box for damages like cracks or chips. Clean it thoroughly to avoid contamination, as dirt or grease may cause shifting of goods during transportation. Position the box on a flat and stable surface.

Planning the Stacking: Before stacking, determine the weight distribution of the goods. Place heavier items at the bottom to ensure load stability and prevent overhanging or wobbling during transportation.

Adding Interlocking Layers: Use cardboard or plastic layers between tiers of goods to stabilize the stack and prevent sliding or shifting during transport.

Securing the Load: Secure the stacked goods using plastic wrap or stretch film, ensuring it’s tight enough to hold the goods in place but not so tight that it causes damage.

Labeling: Label the pallet box with the destination and weight of the goods to ensure proper handling and to avoid exceeding weight limits.

Wrapping for Storage or Transportation: Use strong plastic wrap or stretch film for wrapping. Start by securing the base, wrap the sides ensuring to overlap each layer, and then wrap the top. Finally, secure the film’s end properly.

Choosing the Right Storage Area: Store the pallet boxes in a dry, clean, and well-ventilated area, away from direct sunlight, extreme temperatures, or damp conditions.

Preparing Pallets for Storage: Clean the pallets thoroughly with mild detergent, rinse them off, and let them air dry completely. Inspect each pallet for damage and repair or replace if necessary.

Organizing the Storage: Neatly and evenly stack the pallets, placing larger ones at the base and smaller ones on top. Use straps, bungee cords, or stretch wrap to secure them in place, and label each pallet with size, weight capacity, and storage date.

Adhering to these guidelines ensures the safe and effective use of plastic pallet boxes, enhancing their longevity and functionality in various industrial applications.

Cleaning and Maintenance of Plastic Pallet Boxes

For optimal performance and hygiene, follow these steps to clean and maintain Plastic Pallet Boxes, including stackable boxes, tomato pallet boxes, and pallet plastic boxes:

Remove Loose Debris: Begin by sweeping away any dirt or debris.

Prepare Cleaning Solution: Use a mild detergent or disinfectant, appropriate for plastic, as per manufacturer’s instructions.

Apply Solution: Evenly distribute the cleaning solution over the box using a spray or pressure washer.

Scrub: Scrub the surface with a soft brush or pad to remove dirt and stains.

Rinse: Thoroughly rinse with water, avoiding high pressure that could damage the box.

Dry: Ensure boxes are completely dry before stacking or reusing to prevent mold or mildew.

Do’s and Don’ts:

- Do: Regularly clean based on use and environmental exposure, using soft brushes and ensuring all cleaning agents are rinsed off.

- Don’t: Avoid harsh chemicals, bleach, or high-pressure jets that can harm the plastic. Don’t stack boxes while wet to prevent microbial growth.

Adhering to these practices will help maintain the condition of your Plastic Pallet Boxes, ensuring they remain a durable and hygienic option for various applications.

Applications of Plastic Pallet Boxes Across Various Industries

Plastic Pallet Boxes, including Stackable Pallet Boxes, are versatile and widely used in many industries. Their durability and adaptability make them suitable for various applications, such as:

Logistics and Supply Chain

Essential for efficient and economical transportation and warehousing, tailored for industrial applications. Word count remains unchanged.

Fruit Industry

Ideal for their enhanced heat dissipation and impact resistance, ensuring the safe transportation of delicate fruits.

Apparel Storage Excellence

Sturdy, sustainable plastic pallets designed for secure, space-efficient, and high-capacity garment storage needs.

Choosing the Right Plastic Pallet Box Manufacturer or Supplier

When selecting a manufacturer or supplier for Plastic Pallet Boxes, including stackable options, consider these factors:

Industry Certifications: Verify certifications like ISO9001 for quality assurance and compliance.

Product Variety: Look for suppliers with a diverse range of pallet boxes, reflecting their expertise and ability to meet different needs.

After-sales Support: Choose suppliers offering strong after-sales services for long-term reliability.

Compliance with Safety Standards: Ensure they adhere to relevant safety and industry regulations.

Reputation and Customer Feedback: Research their market reputation through customer reviews and references.

Technical Expertise: Evaluate their knowledge in providing guidance on the best pallet boxes for your requirements.

Customization Capabilities: Check if they offer customization options to meet specific needs.

Transparent Pricing and Communication: Prefer suppliers with clear pricing structures and effective communication channels.

Selecting the right supplier involves assessing their ability to provide quality products and services that align with your specific requirements in using Plastic Pallet Boxes.

Get in Touch

Submit Your Inquiry

Connect with us to discuss your plastic pallet needs. Our team is ready to provide solutions tailored to your specific requirements. Whether it’s a question about our products, a request for a quote, or a need for custom solutions, we’re here to assist you.

Ashley Wang

- Optics Valley Software Park, Huangdao District, Qingdao City, Shandong Province, China

- +86 187 2470 7180

- ashley@enlighteningplast.com