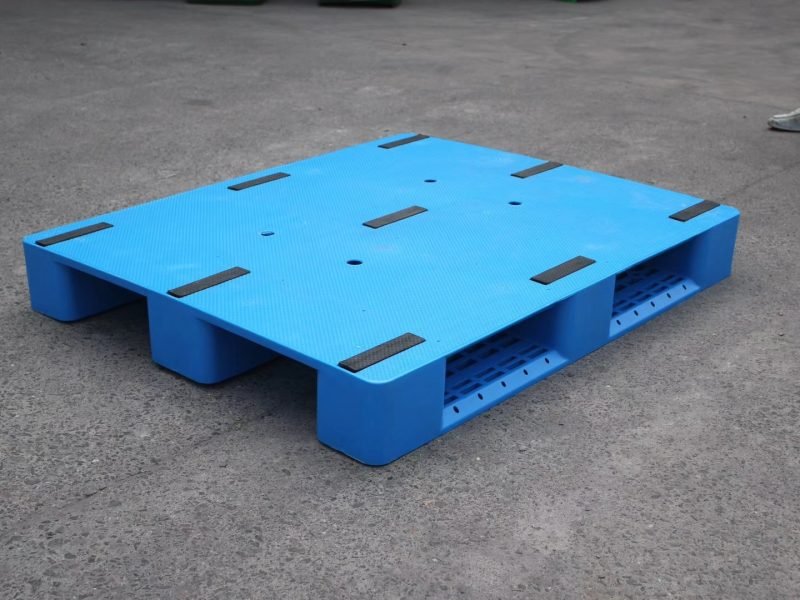

In today’s rapidly developing environment, plastic pallets have clearly become a necessity in the food industry, the pharmaceutical industry, and the logistics industry. Our Enlightening plastic pallets have become the first choice in many industries because of their long durability, excellent load-bearing capacity, and customizable options, non-porous surfaces, perforated surface options, and reusable features.

Why Clean Plastic Pallets?

During any transportation or load-bearing process, plastic pallets can accumulate dirt, dust, grease, etc., over time. While their rugged construction allows them to withstand quite harsh environments, regular cleaning is also key to extending their life and keeping them running smoothly.

Cleaning Pallets is Essential for Several Reasons

Hygiene maintenance: In industries where hygiene is critical, such as the food and pharmaceutical industries, not cleaning pallets for long periods can lead to product contamination and even legal problems. Dirty pallets can also affect the cargo of the entire pallet.

Extend the service life: After proper cleaning and maintenance, the plastic tray can be used for a longer time, greatly reducing the cost of replacement and maintenance. This is particularly true whether you buy plastic pallets as cheap plastic pallets or invest in heavy-duty plastic pallets; proper care extends their usability.

Plastic Tray Cleaning Method

To keep your Enlightening plastic pallets performing at their best, cleaning is key. Our pallets come in two main types: open trays with perforated surfaces that allow easy water flow, and closed trays with smooth, non-porous surfaces for enhanced hygiene. Let’s explore three effective cleaning methods tailored to these designs.

Manual Cleaning

For small businesses, manual cleaning is a great start. Before you begin, gather a soft brush, lukewarm water, and an antibacterial cleaner. Scrub the surface of open trays gently to let water flow through, removing dirt easily. After cleaning, air-dry the tray fully to prevent moisture buildup—perfect for less stringent hygiene needs.

High-Pressure Cleaning

For industries like pharmaceuticals, we recommend high-pressure cleaning. Start by checking your closed trays for chemical residue. Use a pressure washer with hot water and mild detergent to blast away grime, focusing on smooth surfaces. Once done, dry the pallet immediately to avoid water spots, ensuring it’s ready for sterile environments.

Steam Cleaning

Steam cleaning is ideal for deep sanitation. Using a steam cleaner, apply high-temperature steam to disinfect open trays, as they handle heat well. Be cautious—closed trays may warp under extreme heat. The downside? Equipment costs can be high. After steaming, let the pallet cool naturally to maintain its durability and hygiene.

Advantages and Disadvantages of Manual Cleaning

Advantages: Low-cost options that require only basic equipment.Ability to focus on cleaning specific areas where dirt accumulates.

Cons: Time-consuming.Using different cleaning agents, the cleaning effect will vary. May not be suitable for large-scale operation.

Conclusion

Regularly cleaning your plastic pallets, whether they are standard models or specialized heavy-duty plastic pallets, ensures they perform optimally. Investing in proper maintenance can save significant costs over time, particularly if you buy plastic pallets that are priced lower initially. Maintaining even cheap plastic pallets effectively can extend their life significantly, proving that initial savings are only part of the value equation.