You thought pallets were just wooden platforms? Think again. In a world where every millimeter matters, choosing the wrong pallet size could mean delayed shipments, forklift jams, and even… warehouse staff giving you that look. But don’t worry—we’re here to help.

This isn’t just about size—it’s about making logistics smoother, safer, and smarter. With a plastic pallet manufacturer like us, you’ll get eco-friendly, ISO 9001-certified solutions that fit your containers, trailers, and forklifts like a glove. Ready to stop playing Tetris with your shipments? Let’s dive in.

What Are the Standard Pallet Sizes Worldwide?

When managing logistics or storage, knowing the standard pallet dimensions can save time and costs. You don’t want to pick the wrong size and face delays or extra expenses.

Across the globe, there are six ISO standard pallet sizes that support international trade. These dimensions are recognized as the standard pallet specifications for use in container shipping and cross-border logistics. Here’s a simple breakdown:

| Dimension (mm) | Dimension (inches) | Typical Use and Region |

|---|---|---|

| 1200 x 1000 | 47.24 x 39.37 | Commonly used in Europe and Asia |

| 1219 x 1016 | 48 x 40 | The most typical pallet size in North America, often called the GMA standard |

| 800 x 1200 | 31.5 x 47.24 | Known as the Euro pallet, fits European doorways and racks |

| 1100 x 1100 | 43.3 x 43.3 | Popular in Asia, especially for consumer goods |

| 1165 x 1165 | 45.9 x 45.9 | Standard in Australia, designed for railway containers |

| 1067 x 1067 | 42 x 42 | Used in North America, Asia, and Europe for chemicals and telecom equipment |

These standard pallet dimensions and weight standards exist to ensure compatibility with containers, racks, and forklifts worldwide. For example, the standard pallet height is often around 144-160 mm, and the standard size pallet weight varies depending on material and construction.

In addition to these ISO sizes, certain markets prefer local standards. In Singapore, you’ll often see 1100 x 1100 mm or 1200 x 1000 mm pallets, aligning with both regional and ISO preferences. This makes it easier for exporters to comply with international pallet dimensions without needing to switch pallets at their destination.

Now that you know the typical sizes, you’re better prepared to make decisions that fit your shipping and storage needs. In the next section, we’ll look at how these sizes affect your operations.

How Do Standard Pallet Sizes Affect Logistics and Warehouse Operations?

You might be wondering, why does pallet size matter so much in logistics? Let’s break it down and see how standard sizes impact real-world operations.

Space Utilization and Storage Efficiency

Using the right pallet size helps maximize your warehouse capacity. A standard pallet size, like 48×40 inches, fits snugly into container slots and warehouse racks, minimizing wasted space. For example, a 1200×800 mm pallet fits European aisles perfectly, while a 1219×1016 mm pallet works best in North American layouts.

This means more products per shipment and smoother storage workflows.

Transport Compatibility and Efficiency

If your pallets don’t match standard container or truck sizes, you might face problems like reduced loading capacity, extra re-palletizing, and delays. Standard pallet dimensions, like the common 48×40 inches or 1200×1000 mm, ensure seamless loading into trailers and shipping containers.

This keeps goods moving and reduces handling costs at transfer points.

Handling and Operational Flow

Standard sizes make it easier for forklifts, pallet jacks, and automated systems to operate without hiccups. A typical pallet size guarantees smooth movement through automated systems, preventing jams and manual rework.

Imagine trying to load a non-standard pallet into an automated warehouse – it’s not worth the risk.

By choosing pallets that follow standard pallet dimensions and weight, you’ll improve your logistics flow and cut down on potential risks and costs. Next, we’ll explore why these sizes were chosen in the first place and how they shape the industry today.

Why Were These Sizes Chosen?

Have you ever wondered why certain standard pallet sizes became so common? It’s not random—these sizes were chosen for good reasons that balance practicality and logistics needs.

Standard pallet sizes aren’t just a coincidence; they’re a result of careful design and decades of trial and error.

Here are the key reasons behind these choices:

- Transport Compatibility: The standard pallet length and standard pallet height were designed to fit shipping containers, trucks, and warehouse racks. For example, the 48×40 inches pallet fits perfectly in North American trailers, while the 800×1200 mm pallet fits European doors and racks.

- Weight and Handling: The standard size pallet weight matters because heavier pallets can carry more but are harder to handle. Lighter pallets improve handling but may limit capacity. The balance depends on the application.

- Trade and Regional Standards: Early global trade needed sizes that worked across regions. This led to international pallet dimensions that fit rail, truck, and sea transport without needing to repack goods.

| Factor | Example |

|---|---|

| Standard pallet length & width | 48×40 inches fits North American trailers |

| Standard pallet height | Optimized for rack compatibility |

| Typical pallet size weight | Balanced between strength and handling |

| International pallet compatibility | Works with trucks, railcars, and containers |

So next time you see a typical pallet size, remember it’s not just about the wood or plastic. It’s a solution crafted through years of logistics challenges.

How to Choose the Right Pallet Size for Your Business

Choosing the right pallet size isn’t just about picking a number. It’s about matching your product, shipping method, and customer needs. Here’s how you can make that choice with confidence.

Ask yourself these key questions:

- What is the size and weight of your product? A typical pallet size like 48×40 inches works for many products, but heavier or larger items might need custom or plastic pallet dimensions.

- Where are you shipping? If your goods move internationally, consider international pallet dimensions that fit trucks, containers, and racks worldwide.

- How will you handle the pallets? Think about forklifts, pallet jacks, and whether you need standard pallet specifications for automated systems.

Here’s a quick reference to help you decide:

| Product Type or Condition | Suggested Pallet Size |

|---|---|

| Light, high-volume goods (e.g., consumer products) | 1200×800 mm (Euro pallet) |

| Heavy or bulk products | 48×40 inches or custom sizes |

| International shipping with containers | 1219×1016 mm (standard for North America) |

| Tight warehouse spaces (narrow aisles) | 800×1200 mm or 1100×1100 mm |

| Perishable goods requiring cold chain logistics | Plastic pallets with precise dimensions, e.g., 1200×1000 mm |

| Fragile items needing high stability | Solid deck or double-faced pallets |

| Chemical products or hazardous materials | CP pallets (e.g., CP1-CP9) with reinforced specs |

| Automated warehouse operations | Standard pallet specifications (e.g., 1200×800 mm with RFID) |

A few more tips:

- Check the standard pallet length and standard pallet height of your chosen size against your warehouse layout.

- Balance product protection with space efficiency. Oversized pallets may waste space, but undersized ones may damage goods.

- Consider the standard pallet size weight—heavier pallets might carry more, but could slow down handling.

In the end, your best choice depends on your product, operation scale, and customer requirements. Choosing the right pallet isn’t just a logistics decision—it’s a way to save time, reduce costs, and keep your supply chain running smoothly.

What Happens If You Choose the Wrong Pallet Size?

You pick a pallet just a bit too big for your racks.

Your warehouse crew ends up wasting precious space. Aisles get blocked, forklifts struggle, and your storage costs quietly climb.

You select a pallet that’s too small for your heavy goods.

Now, the load tilts dangerously, and your safety team is alarmed. One shift later, a damaged product spills on the floor.

You choose a pallet size that’s not recognized by your international partners.

Suddenly, customs delay your shipment. The goods sit waiting while you pay extra for repacking and storage.

You think a non-standard pallet will save costs upfront.

Turns out, it won’t fit your automated system. Robots stop, manual handling starts, and your efficiency drops by the hour.

You didn’t check standard pallet specifications against your customer’s needs.

The result? A rejected delivery, returned goods, and a damaged reputation you’ll need to repair.

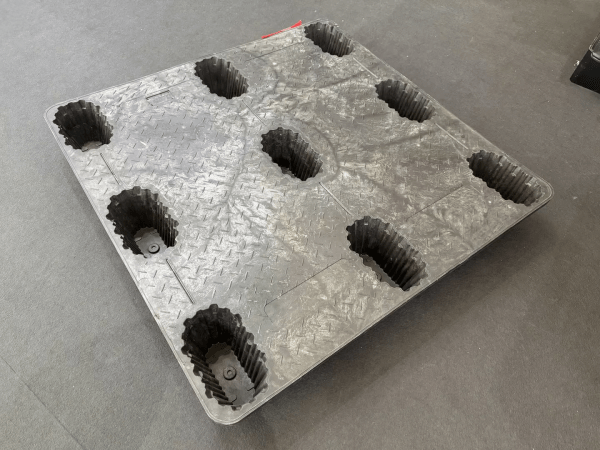

How Does Standard Pallet Size Relate to Plastic Pallets

Standard sizes aren’t just for wooden pallets. If you’re using plastic pallet dimensions, you’ll notice they match key sizes like 48×40 inches or 1200×800 mm. Why? Because these sizes are designed to work across the logistics chain.

Here’s how plastic pallets add extra value to standard sizes:

- Precision: Unlike wood, plastic pallets maintain consistent pallet measurements. Whether it’s the standard pallet length or standard pallet height, the molded design ensures uniformity—ideal for racking and automated systems.

- Durability and Hygiene: Plastic pallets handle moisture, chemicals, and cleaning much better than wood. That’s why industries like food, pharmaceuticals, and cleanrooms prefer them. They don’t just fit international pallet dimensions; they survive harsh environments.

- Customization Options: Need special features? Plastic pallets can include RFID tags, color coding, or drainage holes while still aligning with typical pallet size standards. No need to compromise on operational needs.

“Choosing plastic pallets with standard dimensions means you’re not just following specs—you’re optimizing your supply chain.”

If you’re aiming for precision, durability, and compliance while sticking to recognized standard pallet dimensions, plastic pallets might be your best choice. They don’t just meet the standards; they make them work smarter.

Beyond Standard Sizes: When Do Companies Use Custom Pallets?

Of course, standard isn’t always enough. Sometimes your operation needs more flexibility. That’s when custom pallets come into play.

Think about products that don’t fit the usual footprints. Oversized machinery, oddly shaped packages, or special handling requirements can all lead to custom sizes. In these cases, a typical pallet size just won’t work.

Custom pallets are also essential for unique warehouse layouts. If your aisles are tighter or your racks are higher, you may need a custom plastic pallet that matches the available space and handling systems.

Here’s why companies often choose non-standard pallets:

- Product-specific needs: Large, fragile, or irregular items need special support and protection.

- Warehouse constraints: Limited space or unusual rack designs require adjusted pallet measurements.

- Process efficiency: Custom pallets can reduce handling time by fitting seamlessly into specialized systems.

- Branding and tracking: Custom plastic pallet dimensions allow for color coding, logos, and embedded tracking chips.

Also, custom pallets—especially plastic ones—offer durability and consistency. With precise standard pallet length and standard pallet height, plastic designs minimize variation and maximize operational stability.

“Choosing a custom pallet isn’t just about size—it’s about efficiency, safety, and control over your logistics.”

So, if your operation pushes beyond standard shapes and sizes, consider custom plastic pallets. They’re not just made to fit—they’re made to optimize.

Custom Plastic Pallets: The Smart Move for Your Logistics

Understanding standard pallet sizes is just the beginning. With us as your trusted plastic pallet manufacturer, you get tailored solutions that streamline logistics, reduce risks, and cut costs.

Our plastic pallets fit your product’s exact needs—ensuring smoother operations, less waste, and maximum efficiency. No more costly delays or repacking.

Stop settling for one-size-fits-all. Our custom plastic pallets are built from eco-friendly materials, designed for seamless use in containers, trailers, and forklifts, and fully compliant with ISO 9001 standards. Let’s create the perfect solution for your business today.

Ready to reduce costs and simplify your operations?

Talk to us now for fully customized plastic pallet solutions that fit your products, processes, and compliance needs—so you can focus on what matters.