Editar el contenido

- Parque de Software Optics Valley, Distrito de Huangdao, Ciudad de Qingdao, Provincia de Shandong, China

- +86 187 2470 7180

- ashley@enlighteningplast.com

Injection-molded PP&HDPE rackable stackable plastic pallet with full-perimeter grid deck, four-way entry, and steel reinforcements supports heavy racking. Ideal for cold chain and automated warehousing. Its durable structure and rackable design reduce product damage and ensure safer high-load storage operations. Direct from China factory with bulk pricing.

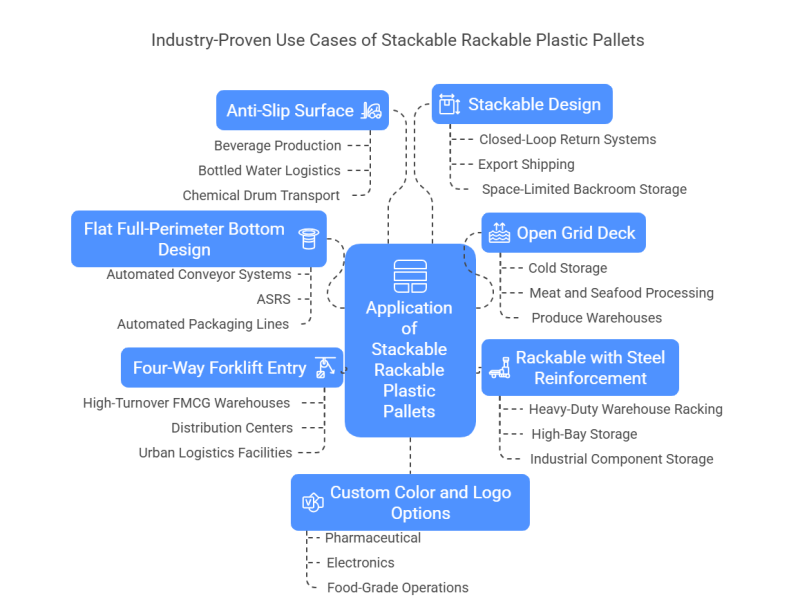

When you’re choosing a single faced plastic pallet for racking or stacking, every detail matters—especially for operations demanding durability, hygiene, and load security. Here’s why this full perimeter pallet stands out:

You don’t just need a plastic pallet—you need a pallet that fits your warehouse, racking, automation, and brand standards. Our factory supports full-spectrum customization to match your operational priorities.

| Category | Key Custom Options |

| Dimensions | Custom length, width, height, foot spacing for automation |

| Structure | Open or closed deck, anti-slip inserts, drainage holes |

| Load Capacity | Adjustable static/dynamic/rack load, optional steel pipes |

| Material | HDPE, PP, recycled or food-grade, with UV/cold resistance |

| Color & Finish | Custom colors, matte or textured surface |

| Branding | Silk screen / IML / hot stamping logo, barcode engraving |

| Smart Features | RFID, QR code, sensor ports for warehouse tracking |

| Certifications | ISO, FDA, REACH, RoHS, 100% recyclable material |

| Industry Adaptation | Cold chain, ASRS, chemical use structure customization |

| Material | HDPE / PP / Recycled Material |

|---|---|

| Dimensions (mm) | 1100 × 1100 × 150 |

| Structure | Full perimeter; One-piece injection molded |

| Deck Type | Grid surface |

| Entry Type | 4-way forklift entry |

| Weight (Without Steel) | 14.5 kg |

| Steel Pipe Weight | 7 kg (8 steel reinforcements) |

| Total Weight (With Steel) | 21.5 kg |

| Load Capacity (No Steel) | Dynamic: 1T / Static: 4T |

| Load Capacity (With Steel) | Dynamic: 1.5T / Static: 6T / Racking: 1T |

| Manufacturing Process | One-piece injection molding |

| Container Load Qty | 20FT: 145 pcs / 40HC: 362 pcs |

| Recommended Use | Racking systems, ASRS, automated warehouses |

En Enlightening Pallet, somos más que simples palets: somos su socio estratégico en la eficiencia de la cadena de suministro.

Distrito de Huangdao, Ciudad de Qingdao, Provincia de Shandong, China

Contact Us Online

Receive a response within one business day. Please look out for emails from “ashley@enlighteningplast.com” to ensure timely and efficient communication.

*Rest assured, your email details are held in strict confidence and will never be shared with any third party.

Receive a response within one business day. Please look out for emails from “ashley@enlighteningplast.com” to ensure timely and efficient communication.

*Rest assured, your email details are held in strict confidence and will never be shared with any third party.

Receive a response within one business day. Please look out for emails from “ashley@enlighteningplast.com” to ensure timely and efficient communication.

*Rest assured, your email details are held in strict confidence and will never be shared with any third party.