What Is The Pallet And Why Does It Matter In Logistics? When we talk about supply chains, we often start with the pallet. It’s the base, the silent supporter that keeps products safe as they move from factory to shelf.

A pallet is a flat structure, usually made from wood or plastic, that holds goods together during storage and shipping. It makes moving large quantities easier and faster.

You might wonder, why is the pallet so critical? Without it, each box or product would need to be handled separately, slowing down operations and increasing costs. Pallets allow forklifts and pallet jacks to lift and move stacks of products at once.

In logistics, choosing the right pallet type can make a big difference. The classic debate of plastic pallets vs wooden pallets is more than just about material—it’s about durability, safety, and overall efficiency. In the next sections, we’ll dive deeper into how each type performs and which might suit your business best.

What Is Plastic Pallets And How Do They Work?

Plastic pallets are platforms made from durable materials like HDPE, PP, or recycled plastics. These pallets resist moisture, bacteria, and pests, making them ideal for industries such as food and pharmaceuticals. Unlike wood pallets, they come in solid or open-grid designs, offering options for hygiene-critical or airflow needs.

Their smooth, non-porous surfaces make them easy to clean and maintain. Lightweight yet strong, plastic pallets don’t splinter or absorb moisture like wood, ensuring safer handling and lower shipping costs. They’re also customizable and support sustainability goals, providing long-term value over traditional wooden options.

What Is A Wood Pallet And Where Are They Used?

A wood pallet is a structure built from solid planks or panels, joined by nails or screws to form a sturdy base for stacking and transporting goods. It’s commonly used in industries such as manufacturing, construction, agriculture, and general logistics. But wood’s porous nature makes it unsuitable for sensitive goods like food or pharmaceuticals.

Key points about wood pallets:

- Weight depends on build: Typically 30–70 pounds (about 13–32 kg).

- Handles heavy loads: Ideal for robust and bulk materials.

- Easily repairable: Damaged parts can be replaced for reuse.

- Lower cost upfront: More economical than plastic for one-way shipping.

Weight Of Wood Pallet Vs Plastic – What’s The Difference?

Weight isn’t just a number—it directly impacts shipping costs, safety, and handling efficiency. Here’s a quick look at how wood and plastic pallets compare:

| Pallet Size (mm) | Plastic Pallet Weight (kg) | Wood Pallet Weight (kg) | Weight Difference (kg) |

|---|---|---|---|

| 755 x 755 | 6.2 | 15 | 8.8 |

| 1000 x 1000 | 14.6 | 25 | 10.4 |

| 1200 x 1000 | 17.6 | 30 | 12.4 |

| 1300 x 1100 | 21.5 | 35 | 13.5 |

| 1500 x 1500 | 28.5 | 45 | 16.5 |

Note: Wood pallet weights are approximate and can vary based on wood type and moisture content.

Key Takeaway: Plastic pallets are significantly lighter than wood pallets of the same size. This weight difference can lead to lower shipping costs and easier handling, especially in industries where weight is a critical factor.

Wood Pallets Vs Plastic Price Comparison – Initial Vs Long-Term Costs

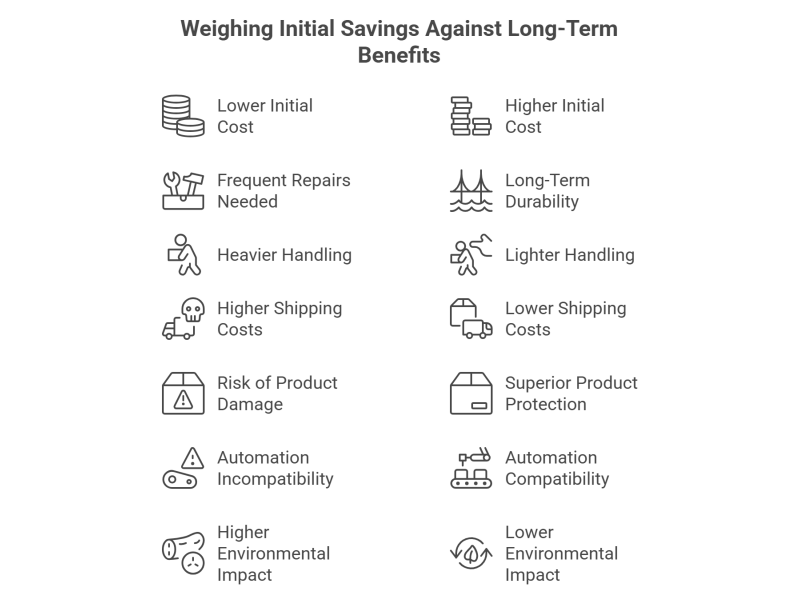

When choosing between plastic pallets vs wood pallets, price isn’t just about the upfront number—it’s about the long-term value. Let’s compare the key costs.

- Initial cost: Wood pallets are cheaper at first, often 3–5 times less than plastic pallets. But this saving can disappear quickly.

- Long-term costs: Plastic pallets last longer (up to 10 years), don’t splinter, and need fewer replacements. Over time, they save you on repairs and lost product costs.

- Handling and shipping: Plastic pallets are lighter, reducing freight expenses. Their uniform size also works better with automation, cutting labor and errors.

- Environmental costs: Plastic pallets can be recycled and reused more easily, reducing waste and environmental impact.

In the long run, plastic pallets may cost more upfront, but they offer savings that make a real difference for your business.

Wood Pallets Vs Plastic Price Comparison – Initial Vs Long Term Costs

Let’s break down the actual costs for plastic pallets vs wood pallets—not just the initial price, but what you pay over time.

Initial Purchase Cost

Wood pallets cost less upfront—often 3–5 times cheaper—because they’re made from cheap, untreated timber and assembled with simple nails or screws. This keeps initial material and labor costs low, but at the expense of long-term reliability. Plastic pallets cost more because we use high-grade virgin or recycled polymers, precision-molded in one piece, ensuring consistent performance and a professional finish.

Production/Assembly Cost

Wood pallets are quickly assembled from cut planks, nailed or screwed together in basic workshops. This process is fast but lacks precision and structural integrity. Plastic pallets are molded in one piece with advanced equipment, ensuring perfect load-bearing and precise dimensions for automation.

Repair & Replacement Cost

Wood pallets splinter, absorb moisture, and break easily, requiring frequent repairs or full replacements. Damaged pallets increase product loss risks and hidden maintenance costs. Plastic pallets resist impact and moisture, maintaining their shape and function over years of use.

Handling & Labor Cost

Wood pallets are heavier and less ergonomic, increasing manual handling time and injury risks. Frequent replacements and repairs mean more labor hours. Plastic pallets are lighter and smooth-edged, streamlining handling and lowering safety hazards.

Shipping Cost

Wood pallets add significant weight to shipments, driving up freight costs and reducing payload capacity. Fuel use rises as shipping weight increases. Plastic pallets are much lighter, helping to cut shipping expenses and carbon footprint.

Product Damage Cost

Wood pallets break under load or during handling, risking damage to high-value goods. Splinters and protruding nails can also cause contamination. Plastic pallets are engineered to be strong, smooth, and hygienic, offering superior product protection.

Automation Compatibility Cost

Wood pallets vary in size and condition, disrupting conveyor and ASRS flow. Inconsistent dimensions can cause jams or misreads in automated systems. Plastic pallets are uniform and precisely molded, ensuring smooth, error-free integration into automation.

Environmental & Disposal Cost

Wood pallets degrade over time but break often, creating constant waste and higher disposal fees. Splinters and nails complicate recycling. Plastic pallets are recyclable and reusable in closed-loop systems, reducing long-term waste and environmental impact.

So while wood pallets may look cheaper at first, the hidden costs add up fast. Plastic pallets offer long-term savings and greater operational efficiency.

Wood Vs Plastic Pallets Environmentally Friendly – Which Is The Greener Choice?

Let’s compare the environmental impact of wood and plastic pallets in real-world use.

Wood pallets come from renewable timber and are biodegradable.

- But they break often, generating more waste and carbon from replacements.

- Frequent repairs and replacements lead to higher disposal costs.

Plastic pallets last longer, cutting replacement and material use.

- They support closed-loop recycling, keeping them in the supply chain.

- Consistent quality reduces product waste and carbon emissions.

So while wood pallets seem greener on paper, plastic pallets offer better long-term sustainability with fewer hidden costs.

Why Plastic Pallets Are The Smarter Investment For Modern Businesses

We know that pallet choice can make or break your operational efficiency. Let’s look at how plastic pallets outperform wood in every key area.

Durability & Long-Term Use

Plastic pallets resist splintering, cracking, and moisture, lasting up to 10 times longer than wood. This durability means fewer repairs, lower replacement costs, and less disruption to your operations.

Automation Compatibility

Plastic pallets have precise dimensions and smooth surfaces, ensuring flawless performance in automated warehouses. This boosts productivity and reduces manual labor errors.

Sustainability & Brand Value

Plastic pallets are fully recyclable and reusable, supporting sustainability goals. Their clean design also enhances your brand’s image, showing your commitment to efficiency and the environment.

Cost Efficiency Over Time

While plastic pallets cost more upfront, their long life reduces ongoing expenses. They cut freight charges with lower weight, fit perfectly into automated systems, and require minimal handling adjustments.

Plastic pallets deliver long-term efficiency and cost savings that wood pallets simply can’t match.

Your Smarter Switch To Plastic Pallets Starts Here – With Enlightening

Switching from wood pallets to plastic isn’t just a change—it’s a game-changer for your operations. Plastic pallets slash hidden costs from replacements, reduce product damage, and streamline automated systems—problems that frustrate B2B clients every day.

At Enlightening, we’re not just suppliers. As experienced plastic pallet manufacturers, we deliver custom solutions designed around your real needs—whether it’s optimizing automated warehouses, ensuring hygiene compliance for food and pharma, or cutting shipping costs with lightweight, durable designs.

Don’t let inefficient wood pallets hold your business back. Talk to our expert team today to get a custom plastic solution that maximizes efficiency, reduces costs, and supports your sustainability goals. Together, we’ll build a more resilient, productive, and profitable future for your company.

👉 Contact us now for a personalized consultation and quote. Let’s optimize your supply chain, one smart plastic solution at a time.