Full Perimeter Plastic Pallets

Experience unparalleled durability and efficiency with our Full Perimeter Plastic Pallets, tailored for high-demand industrial use.

Enlightening Pallet: Specializing in Full Perimeter Plastic Pallets

Enlightening Pallet, a prominent Plastic Pallet manufacturer, is proud to offer an advanced range of Full Perimeter Plastic Pallets, meticulously designed to cater to various industrial demands. Our portfolio includes two main types: Grid Top Full Perimeter Pallets and Flat Top Full Perimeter Pallets.

Our portfolio features two primary categories:

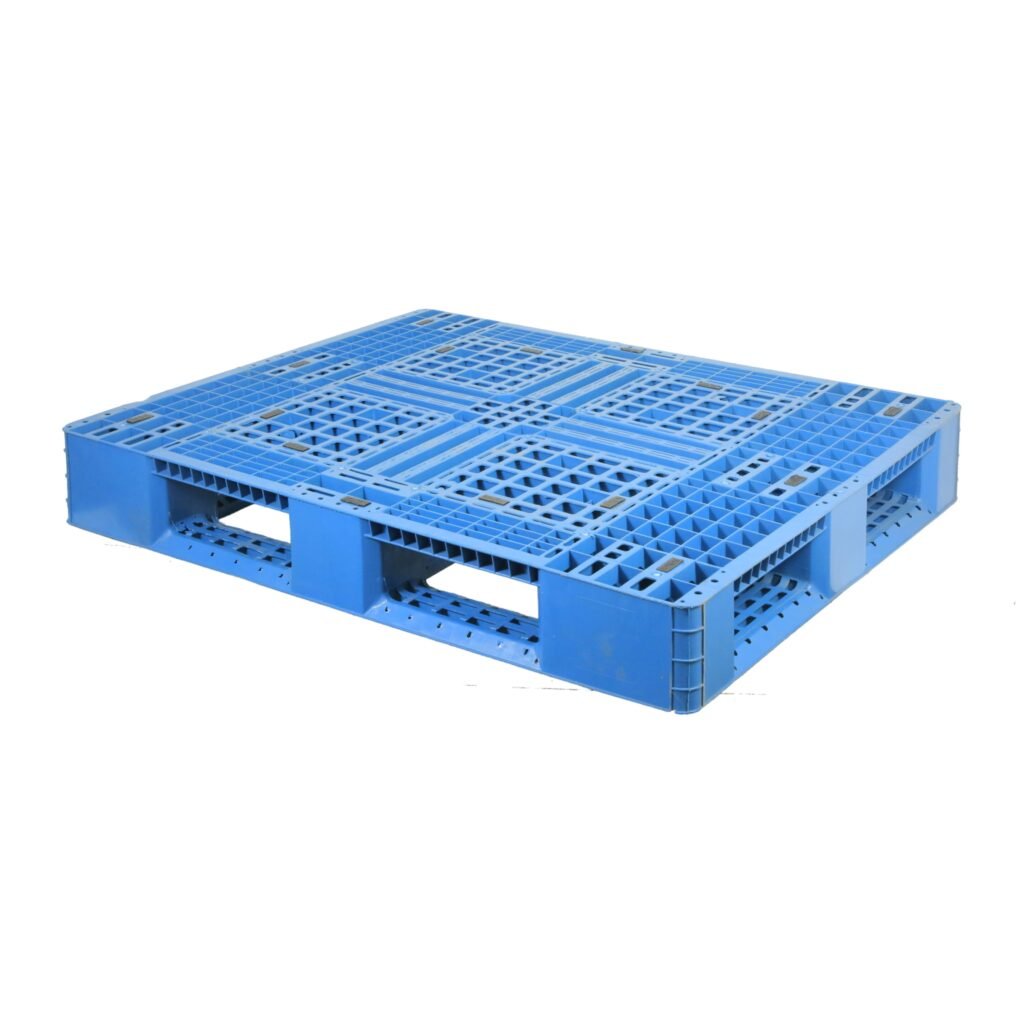

Grid Top Full Perimeter Pallets

Ventilated decks with mesh/grid openings, lighter in weight, cost-effective, and allow easy draining when wet. Ideal for moisture-prone environments.

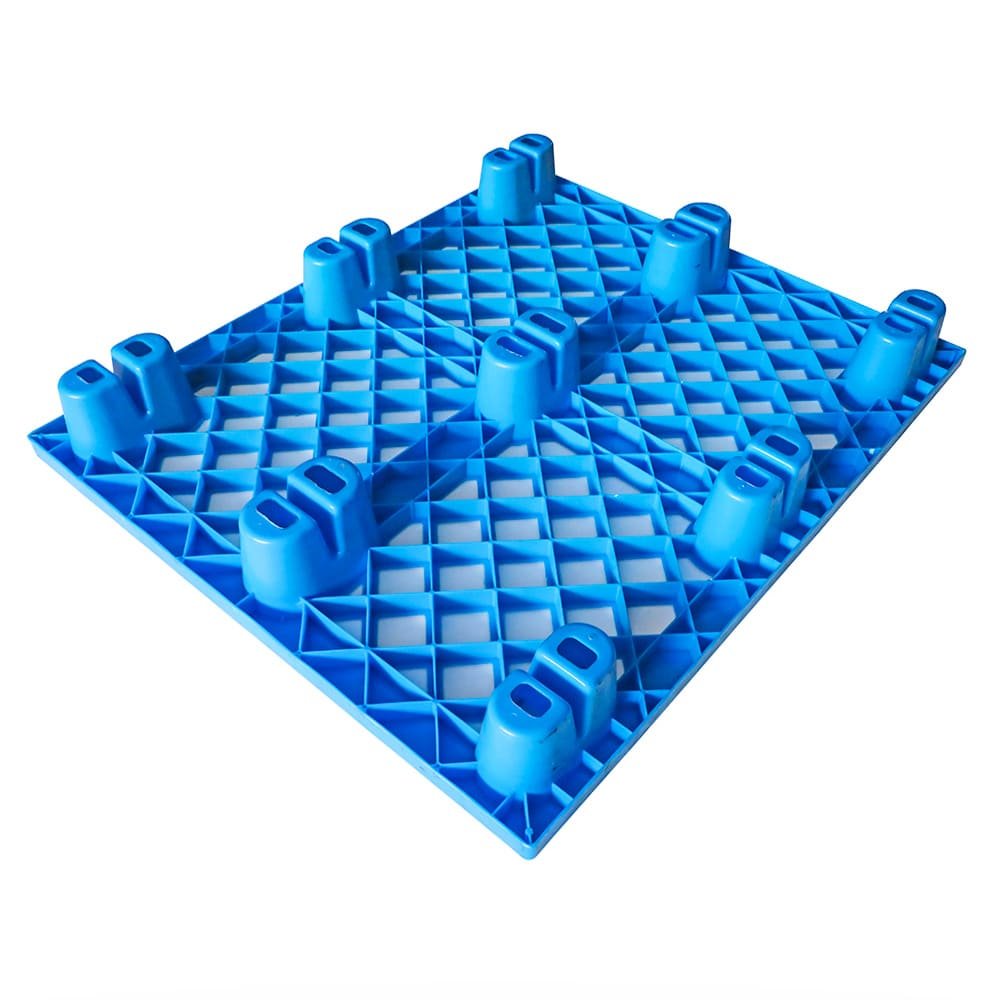

Flat Top Full Perimeter Pallets

Solid top decks with a smooth, solid plastic surface, often featuring anti-skid properties or perimeter lips. Offer great hygiene and are easier to clean

Enlightening Pallet now offers two core models of Full Perimeter Plastic Pallets, optimized for specific storage and transportation needs: the Full Perimeter Grid Plastic Pallet and the Full Perimeter Flat Plastic Pallet. Both models are designed with a focus on robustness, versatility, and eco-friendliness.

Furthermore, Enlightening Pallet specializes in customized solutions, leveraging advanced tool-less molding technology and extensive industry experience. This approach allows for the creation of unique pallets tailored to specific applications, sizes, or equipment needs, without the limitations of standard sizes, tooling costs, or minimum order quantities.

Our commitment to innovation and customer satisfaction ensures that each pallet, whether standard or customized, integrates seamlessly into your logistical and storage systems, enhancing efficiency and sustainability.

Why Choose Enlightening Pallet for Full Perimeter Plastic Pallets

Enlightening Pallet stands as a leader in the Full Perimeter Plastic Pallet market, offering unparalleled solutions that merge innovation with vast industry experience.

Tailored Solutions: We specialize in custom-made Full Perimeter Plastic Pallets, ensuring they meet your unique requirements in efficiency, safety, and sustainability.

Advanced Manufacturing: Our pallets, including Heavy Duty and HDPE Plastic Industrial Pallets, leverage state-of-the-art production technologies, catering to diverse industries like food, medicine, and logistics.

Production Excellence: Our facilities boast over 100 specialized machines, enabling us to produce top-tier Full Perimeter Plastic Pallets that exemplify strength and durability.

Competitive Pricing: We provide high-quality pallets at competitive prices, ensuring excellent value in every investment.

Enlightening Pallet is your ideal partner, dedicated to delivering eco-friendly, durable, and cost-effective Full Perimeter Plastic Pallet solutions.

- Tailored Solutions for Your Business

We understand every client has unique needs. Our approach is to provide custom-made plastic pallets, ensuring they perfectly align with your specific requirements for efficiency, safety, and sustainability. - Advanced Manufacturing Technology

Leveraging cutting-edge production techniques, our plastic pallets are designed to meet the current and emerging demands of various industries, including food, medicine, logistics, and more.

Enlightening Pallet: Con la Confianza de Más de 450,000

Clientes Satisfechos — Su Invitación a Unirse

Comprehensive Guide to Full Perimeter Plastic Pallets

Full Perimeter Plastic Pallets are essential in modern logistics, offering robust platforms for goods in transit and optimizing warehouse storage. These pallets stand out for their unmatched strength, hygiene, and adaptability to various environments.

What is the Full Perimeter Plastic Pallet?

The Full Perimeter Plastic Pallet, distinct from the 9 Legs Plastic Pallet, is a robust and versatile tool optimized for extensive material handling needs. It features a comprehensive perimeter base, providing exceptional stability and support, making it ideal for heavy-duty applications. This pallet type is particularly suited for sectors that demand meticulous handling, such as food, medicine, and logistics, ensuring the safe and damage-free movement of materials. Its design enables smooth and consistent handling, vital for efficient logistics operations, making Full Perimeter Plastic Pallets a crucial asset in storage and transportation.

The Evolution of Full Perimeter Plastic Pallets: A Historical Perspective

The development of Full Perimeter Plastic Pallets is an integral part of the history of plastic pallets. Emerging around the mid-1960s, innovations in plastic pallet design were pioneered by companies like Robinson Industries. Techniques such as injection molding and blow molding were instrumental in their early production. The 1970s saw a proliferation of manufacturers and methods, including thermoforming and rotational molding. Over the decades, advancements in plastic pallet technology have focused on improving durability, strength, and functionality, with Full Perimeter Plastic Pallets evolving as a response to the dynamic needs of modern supply chains.

Advantages of Full Perimeter Plastic Pallets

Durability and Longevity: These pallets are 10 times more durable than wooden pallets, providing unmatched strength and endurance, especially in heavy-duty and closed-loop scenarios.

Efficiency and Investment Return: They are a valuable business asset, lasting significantly longer than wood and offering a high return on investment. Their design is suitable for creating an owned pallet pool, further enhancing their cost-effectiveness.

Hygiene and Safety: Full Perimeter Plastic Pallets are ideal for hygienic areas, as they are smooth, easy to clean, and do not harbor mold or dust. Additionally, they are safer for manual handling, being manufactured without nails, sharp edges, or splinters.

Environmental Sustainability: These pallets are made from recycled materials and can be reground to produce new products, contributing to environmentally friendly practices.

Space and Cost Saving: They offer space-saving solutions in warehouses and during transit, leading to fewer return journeys and a reduced carbon footprint.

Customizability and Versatility: Designed for specific applications, Full Perimeter Plastic Pallets are customizable and suitable for a wide range of uses. They are impervious to moisture, weak acids, and alkalis, ensuring no contamination issues and easy cleaning.

These benefits highlight the Full Perimeter Plastic Pallet’s role as a crucial element in modern logistics, offering heavy-duty performance, HDPE Racking Pallet capabilities, and being a key product offered by plastic pallet manufacturers.

Design Guide for Full Perimeter Plastic Pallets

Specializing in Full Perimeter Plastic Pallets, our designs cater to a broad range of industrial needs. These HDPE Logistic Plastic Pallet are essential for robust and efficient logistics:

Características clave:

- Rigid top deck on a full-perimeter base for superior durability and a long working life.

- Manufactured from recycled or virgin plastic, ensuring environmental responsibility.

- Available in various sizes to meet different logistical demands.

- Options for open or closed top decks, providing flexibility for different types of cargo.

- Standard black color with options available in virgin materials.

- Features like edge lips, RFID inserts, and screen-printed ID for enhanced functionality and tracking.

Key Benefits:

- Reusable design, suitable for long-term repeated use.

- Rackable construction allows easy racking in either direction, handling loads up to 1250kg.

- 100% dimensional accuracy, making these pallets well-suited for automated systems.

Our Full Perimeter Euro Racking Pallet, including variants like Plastic, are designed with a focus on operational efficiency, durability, and customizability, addressing the unique requirements of various industries. Our expertise as plastic pallet manufacturers ensures that we provide solutions enhancing your logistics and storage processes.

Selecting the Right Full Perimeter Plastic Pallets

Choosing the ideal Full Perimeter Plastic Pallet for your business involves several important considerations to ensure they align with your specific needs:

Intended Use: Assess the primary application of the pallets. Full Perimeter Plastic Pallets are suitable for various uses, including storage, shipping, or retail displays.

Size and Space: The size of the pallets should accommodate your products comfortably, and fit well within your storage and transportation facilities.

Durability and Load Capacity: Ensure the pallets can handle the weight of your products to prevent damage. Opt for sturdier pallets for heavier loads.

Hygiene and Safety: For industries like food and pharmaceuticals, choose pallets that are easy to clean, non-absorbent, and comply with regulatory standards.

Sustainability: Consider the environmental impact. Eco-friendly pallets made from recycled materials or designed for recyclability are preferable.

Types of Plastic Pallets: Understand the different types available, such as Rackable, Nestable, Export, and Display Plastic Pallets, each suited for specific purposes.

Compatibility with Automation: With the rise of automation in logistics, consider whether the pallets are compatible with automation machines like AGVs and have features like semiconductors for improved tracking.

RFID Tracking: For improved inventory and tracking management, opt for pallets with RFID technology.

Sustainable Materials: If reducing environmental impact is a priority, look for pallets made from sustainable materials.

By evaluating these factors, you can select the most suitable Full Perimeter Plastic Pallets for your business, ensuring efficiency, durability, and sustainability in your operations.

Decoding the Pricing Structure of Full Perimeter Plastic Pallets

In the realm of plastic pallet manufacturers, understanding the cost dynamics of specialized Full Perimeter Plastic Pallets is key, especially for heavy-duty applications in warehousing. Here’s a breakdown of the factors influencing their pricing:

Material Integrity: When it comes to Plastic Pallets for Warehouse use, the selection of premium-grade materials like HDPE and PP is a vital determinant of price. These materials, renowned for their durability and resilience, make Full Perimeter Plastic Pallets an investment in long-term efficiency.

Advanced Manufacturing Techniques: The production processes such as injection molding, crucial in manufacturing Heavy Duty Plastic Pallets, directly influence the cost. Each technique, particularly injection molding, offers exceptional uniformity and strength but comes with a higher price tag due to the advanced technology involved.

Design Complexity and Specifications: Full Perimeter Plastic Pallets, known for their robust design suitable for heavy loads, can vary in cost based on size, weight capacity, and specific design features like grid or flat surfaces. Customizations to meet industry-specific standards also play a role in the pricing structure.

Volume of Order: In the world of plastic pallet manufacturers, the economics of scale is a significant factor. Bulk orders typically mean lower per-unit costs, offering an advantage to large-scale procurers in sectors like logistics and warehousing.

Market Dynamics: The pricing of Plastic Pallets for Warehouse use is also sensitive to the fluctuations in supply and demand within the market. A surge in demand or a dip in supply can lead to price adjustments.

Added Functionalities: Incorporating additional features like anti-slip surfaces, RFID compatibility, or bespoke branding can elevate the utility of Full Perimeter Plastic Pallets but also influence the final cost. These enhancements should be weighed for their practical benefits in your specific industrial context.

In conclusion, when considering Full Perimeter Plastic Pallets for your warehousing or logistics needs, it’s essential to balance these factors to ensure you receive optimal value and functionality that aligns with your operational requirements.

Manufacturing Process of Full Perimeter Plastic Pallets

Raw Material Selection: The process starts with selecting high-density polyethylene (HDPE) or polypropylene (PP), known for their durability and recyclability. This careful selection is crucial in producing quality pallets.

Advanced Injection Molding: Injection molding is a key technique, where molten plastic fills custom molds. This method is essential for creating strong, intricate pallet designs.

Cooling and Ejection: After molding, pallets undergo a critical cooling phase to ensure structural integrity, followed by a meticulous ejection process.

Customization and Quality Assurance: Offering a variety of sizes and configurations, these pallets are made to suit various industry needs, with a strong focus on quality control.

Environmental Stewardship: Emphasizing sustainability, these pallets are designed for an extended lifecycle and recyclability, aligning with the principles of a circular economy.

This manufacturing process, combining cutting-edge technology and craftsmanship, produces Full Perimeter Plastic Pallets that are essential in modern logistics and supply chain management.

Material Selection for Full Perimeter Plastic Pallets

The choice of materials in manufacturing Full Perimeter Plastic Pallets is critical for ensuring durability, functionality, and cost-effectiveness. Different materials offer unique advantages:

Polietileno de Alta Densidad (HDPE): HDPE is a popular choice due to its versatility, offering a balance between impact resistance and rigidity. It’s also cost-effective, making it a go-to material for a wide range of applications. HDPE is known for its impact resistance, ability to withstand freezing temperatures, and resistance to strong acids and bases, making it suitable for diverse industrial environments.

Polypropylene (PP): PP stands out for its rigidity, surpassing HDPE in this regard. It’s particularly favored when stronger, more rigid pallets are required. However, it does have less impact resistance compared to HDPE and tends to be more expensive. Its excellent crush recovery makes it resilient, suitable for high-stress applications.

Polyolefin (PO): PO, a blend of HDPE and PP, offers the combined benefits of both materials, including high rigidity and cost-effectiveness. It’s an ideal choice for export pallets where durability and cost-efficiency are key. However, it can be challenging to mold and is susceptible to water damage, making it less suitable for certain applications.

Fiberglass: A relatively new material in the realm of plastic pallets, fiberglass offers extreme rigidity and impact resistance. Its natural fire-retardant properties make it an excellent choice for applications requiring high temperature or chemical resistance. While offering superior strength, fiberglass pallets are more expensive and require specialized manufacturing techniques.

In summary, the selection of materials for Full Perimeter Plastic Pallets is a nuanced decision, balancing factors such as impact resistance, rigidity, environmental conditions, and cost. Manufacturers must consider these variables to produce pallets that meet the specific requirements of different industrial applications, ensuring optimal performance and sustainability. Incorporating keywords: Full Perimeter Plastic Pallet, Plastic Pallet Manufacturers, HDPE Plastic Industrial Pallets.

Why Choose Enlightening Pallet for Your Full Perimeter Plastic Pallet Needs?

At Enlightening Pallet, we specialize in the meticulous design and production of Full Perimeter Plastic Pallets, tailored to meet your distinct needs. Our expertise in utilizing premium materials such as HDPE, PP allows us to create a range of pallet types, perfectly suited to your specific demands.

Our seasoned team is committed to providing bespoke solutions, with a keen focus on your detailed specifications. Thanks to our strong alliances with industry-leading manufacturers, we assure the delivery of superior full perimeter plastic pallets.

Choosing Enlightening Pallet goes beyond selecting a product; it signifies a partnership in excellence. We ensure that you receive full perimeter plastic pallets that are not only robust and long-lasting but also represent our commitment to eco-friendliness and unparalleled customer satisfaction.

Comparative Benefits of Plastic Pallets Versus Wooden Pallets

In the realm of plastic pallets, Full Perimeter Plastic Pallets and Nine-Feet Plastic Pallets each present distinct benefits and limitations. Here’s an insightful comparison:

- Robustness and Endurance: Full Perimeter Plastic Pallets, constructed with high-quality HDPE and PP, are known for exceptional strength and durability. These pallets can withstand substantial loads and harsh conditions, making them a cost-efficient choice due to their prolonged lifespan. In contrast, Nine-Feet Plastic Pallets, while also durable, may offer slightly less load-bearing capacity.

- Hygiene and Maintenance: Both pallet types excel in hygiene. The non-absorbent nature of plastic prevents moisture retention and contamination, crucial for sectors demanding high sanitation standards like food and pharmaceuticals. Their easy-to-clean surfaces minimize contamination risks.

- Long-Term Cost Efficiency: Although Full Perimeter Pallets might have a higher upfront cost, they prove more economical over time, thanks to their extended durability and minimal maintenance requirements. Nine-Feet Pallets, while initially more affordable, may require more frequent replacements.

- Handling and Storage: Full Perimeter Pallets provide enhanced stability and uniform load distribution, beneficial for automated handling systems. However, Nine-Feet Pallets are generally lighter and more manageable, offering advantages in manual handling and space-saving due to their nestable design.

- Environmental Consideration: Both Full Perimeter and Nine-Feet Plastic Pallets are typically made from recyclable materials, underlining their eco-friendly nature. They both contribute to reducing environmental waste.

In summary, while Full Perimeter Plastic Pallets offer superior durability, stability, and lifespan, making them ideal for heavy-duty and automated applications, Nine-Feet Plastic Pallets are more suited for lighter loads and space efficiency. Choosing the right type depends on specific operational requirements and handling preferences.

Full Perimeter Heavy Duty Plastic Rack Pallets in Various Industries

Full Perimeter Heavy Duty Plastic Rack Pallets are revolutionizing material handling across diverse sectors. Their robust construction and rackable design make them the preferred choice for industries prioritizing efficiency, safety, and durability. Let’s explore their impact in key sectors:

Automotive Industry: The automotive sector greatly benefits from these pallets, especially for transporting and storing hefty vehicle parts. Their strength and stability, coupled with compatibility with automated systems, make them indispensable for efficient operations.

Industria química: In the chemical industry, the resistance of Full Perimeter Plastic Pallets to a wide array of chemicals and adverse environmental conditions is crucial. Their non-absorbent material is essential for the safe handling and storage of sensitive chemical products.

Food and Beverage Industry: The hygiene-centric food and beverage industry values these pallets for their cleanability and sanitary properties. Their structural integrity ensures safe transportation and storage of food items, aligning with stringent health standards.

Pharmaceutical Industry: Sterility and contamination control are vital in pharmaceuticals, and Full Perimeter Heavy Duty Plastic Rack Pallets excel here. Their non-porous surfaces are easy to sanitize, making them a go-to choice for this sector.

Petroleum and Lubricant Industry: For the petroleum industry, these pallets offer a protective barrier against environmental elements, ensuring the safe transportation of petroleum products.

Handling and Use of Full Perimeter Heavy Duty Plastic Pallets

When utilizing Full Perimeter Heavy Duty Plastic Pallets, it’s essential to follow certain guidelines to ensure their optimal performance and longevity:

Selecting the Appropriate Pallet: Choose Full Perimeter Plastic Pallets based on the specific needs of your load. These pallets, available with five or six runners, are designed for maximum strength, making them ideal for racking or pool applications and universal in pallet loops.

Load Capacity Considerations: Understand the load capacity of your plastic pallets. While they have a safety margin for maximum loads, it’s crucial that the load is evenly distributed. If the load is concentrated in the center, adjust accordingly. Also, consider external environmental factors that might affect load capacity.

Selección de Material: Full Perimeter Heavy Duty Plastic Pallets are typically made from virgin or recycled HDPE or PP. HDPE is known for good shock absorbing performance, especially in low temperatures, while PP maintains its robust structure at higher temperatures, offering excellent performance on racking.

Regular Inspection and Maintenance: Inspect pallets regularly for any signs of wear or damage, such as cracks or deformation. Maintaining the pallets in good condition ensures safety and extends their service life.

Proper Storage: Store the pallets in a dry, clean, and well-ventilated area, away from direct sunlight and extreme temperatures, to preserve their integrity.

Safe Handling Practices: Always adhere to safe handling practices, including using appropriate lifting equipment and techniques, to reduce the risk of injury and damage to the pallets or the load.

These guidelines will help in maintaining the integrity and performance of Full Perimeter Heavy Duty Plastic Pallets, ensuring efficient and safe usage in various industries, including automotive, chemical, food, beverage, and pharmaceuticals. By incorporating keywords such as Heavy Duty Pallets and plastic pallets manufacturers, this tailored web copy aligns with your business focus and the specific needs of your target market.

Cleaning and Maintenance of Plastic Pallets

Ensuring the cleanliness and maintenance of Full Perimeter Heavy Duty Plastic Pallets is crucial for their longevity and performance. Here’s a comprehensive guide:

Manual Cleaning Method:

- Initial Cleaning: Begin by using an air compressor to remove dust, grass, leaves, or other debris from the pallet surface.

- Washing: Hose down the pallets with water, then scrub with all-purpose, heavy-duty soap to remove any debris or spills.

- Sterilization: Apply a heat treatment using a steam cleaner to sterilize the pallets and eliminate additional germs.

Using High-Pressure and Automated Washers:

- Deep Cleaning: For applications involving pharmaceutical, food, or chemical products, use a pressure washer for a more thorough clean.

- Durable Cleaning: Full Perimeter Heavy Duty Plastic Pallets can withstand high-pressure water and stronger soaps, making them suitable for rigorous cleaning processes that remove dirt and residue buildup.

Heat Sterilization Method:

- Sterilization Process: Heat sterilization is essential to ensure pallet sterility. This method effectively removes grease, chemicals, or dirt, providing a deep, hygienic clean.

- Temperature Requirements: Ensure that the temperature reaches a minimum of 165 degrees Fahrenheit. This process should be conducted in a designated cleaning room. After cleaning, pallets can be wrapped or bagged for storage if not needed immediately.

Do’s and Don’ts:

- Do: Use a soft brush or pad to avoid scratching the pallets. Ensure all cleaning solutions are thoroughly rinsed off. Regular cleaning based on usage frequency and environmental exposure is recommended.

- Don’t: Avoid using bleach or harsh chemicals that can degrade plastic materials. Do not stack damp or wet pallets, as this can promote the growth of mold and other microorganisms.

By following these guidelines, Full Perimeter Heavy Duty Plastic Pallets can be maintained in top condition, ensuring they remain a reliable solution for various industries.

Applications of Plastic Pallets Across Various Industries

Plastic Pallets, including specialized variants like Plastic Freezer Pallets and HDPE Logistic Plastic Pallets, are essential in various industries due to their distinct features and benefits.

Logistics and Supply Chain

Essential for efficient and economical transportation and warehousing.

Food and Chemical Industries

Preferred for their heat dissipation and impact resistance, ensuring safe transport of sensitive goods.

Warehouse Storage

Rackable pallets cater to heavy-duty storage needs with high load capacities.

Choosing the Right Heavy Duty Plastic Pallets Manufacturer or Supplier

Selecting an appropriate manufacturer or supplier for heavy duty plastic pallets is a critical decision that impacts the efficiency of your supply chain. Here are key factors to consider, enriched with insights from top manufacturers:

Industry Certifications: Prioritize manufacturers with certifications like ISO 9001, which ensures quality and regulatory compliance. For example, Shanghai Favors Packaging Technology Co., Ltd. has both ISO 9001 quality and ISO 14001 environmental management system certifications.

Product Range and Innovation: Look for suppliers offering a diverse range of pallet types, indicating broad expertise. For instance, companies like LY Plastic Pallet and FAVOS offer a wide variety of pallets, including custom options to meet specific customer needs.

Reputation and Reviews: Assess their reliability through customer feedback and references. Companies with a good reputation worldwide, such as FAVOS, are often a safe choice.

Technical Expertise and Experience: Evaluate their industry experience and technical knowledge in manufacturing plastic pallets. Manufacturers like Polymer Solutions International, with years of experience, offer products with a focus on sustainability and high performance.

Opciones de personalización: Check if they offer customization for specific requirements, as companies like PSI® do, ensuring unique needs are met.

Transparent Pricing and Communication: Opt for suppliers with clear pricing and effective communication to avoid hidden costs. It’s also beneficial if they offer free samples for testing, as some manufacturers do.

Sustainability Focus: Choose manufacturers focusing on sustainability, using recycled materials, and offering recyclable products, as demonstrated by companies like Plasgad.

Global Presence and Versatility: Consider manufacturers with a global footprint and versatility in their product offerings, like ORBIS, which has expanded its presence in the European market.

By considering these factors, you can identify a reliable heavy duty plastic pallet manufacturer or supplier that meets your specific business needs, ensuring the smooth functioning of your supply chain

Contáctenos

Envíe su Consulta

Póngase en contacto con nosotros para hablar sobre sus necesidades de palets de plástico. Nuestro equipo está listo para ofrecer soluciones adaptadas a sus requisitos específicos. Ya sea una consulta sobre nuestros productos, una solicitud de cotización o una necesidad de soluciones personalizadas, estamos aquí para ayudarle.

Ashley Wang

- Parque de Software Optics Valley, Distrito de Huangdao, Ciudad de Qingdao, Provincia de Shandong, China

- +86 187 2470 7180

- ashley@enlighteningplast.com